|

|

|

|

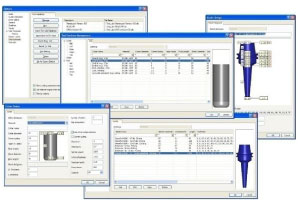

NCG CAM can store a wide range of tool-holders and cutting tools in separate libraries but linked, so the users can set-up a range of holders which are suitable for use with the cutting tool.

Both the cutting tools and holders can be created graphically and then stored in the relevant library. These libraries can be specified and named for individual machine tools or materials, and set-up to have tool numbers, spindle speeds, rapid feed, ramp feed, cutting feed and coolant or air blast options. |

|

|

Tool sheets are automatically created in XML / HTML format and have the option to include graphics. The tool sheets are vital if the part is to be machined by someone other than the person who programmed it. For parts that are machined quite often, (a forge die being a good example), may be on the machine 2 or 3 times a week for a re-cut. The tooling sheet ensures the operator knows which tool and tool size machines each part. |

|

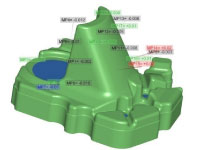

NCG CAM has an inspection module which allows the machined part to be inspected while still on the CNC machine tool. NCG CAM has an inspection module which allows the machined part to be inspected while still on the CNC machine tool.

This functionality is particularly useful for large components which take valuable time to remove off the machine tool, send to the inspection department, and set-up again if re-machining is required. Other applications that the part inspection is useful for are for complex 3D doubly curved components which can only be inspected to the original surface model, or for the checking spark-erosion electrodes for accuracy of negative spark-gap allowances prior to being used in the spark erosion process.

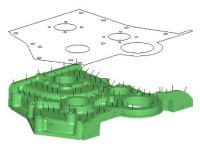

Inspection vectors are created graphically on the surface model by the user, or a blanket grid can be made automatically within a given boundary. These vectors are then converted to inspection probe motions, which are sent to the CNC machine.

|

This in turn sends back data to the part inspection file which compares the machined part with the original surfaces. The results can be displayed graphically, in tabular form , as a table on the computer screen, or as an Excel spreadsheet. This in turn sends back data to the part inspection file which compares the machined part with the original surfaces. The results can be displayed graphically, in tabular form , as a table on the computer screen, or as an Excel spreadsheet.

Since the inspection takes place on the machine tool, should there be the need for any further machining, it can be carried out straight away, saving valuable time.

The part inspection is currently available on CNC machines with Heidenhain controls that support probing. |

|

|

|

|

|