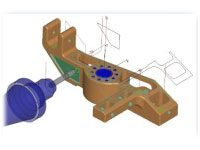

3+2 multi-axis machining has an easy to use graphical interface, including being able to snap to the surface normal for machining.

This enables the user to reach deep and complex areas by rotating the part or the head of the machine tool through a combination of A, B or C motion. Once in position, all machining routines are available and are fully gouge protected for the tooling and the holder and can be used in conjunction with cutter contact angles. |

|

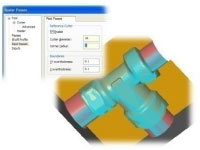

NCG CAM has rest area machining options on all the finishing routines, such as waterline, raster, spiral, radial, constant step-over, parallel pencil passes, corner offset passes, morphed and boundary passes.

This allows the input of the previously used cutter size or reference cutter to be specified. Passes will only be generated in areas that are inaccessible to the reference cutter. All rest area calculations can be done without the need for boundaries, and steep and shallow cutter contact angles can be applied. |

|

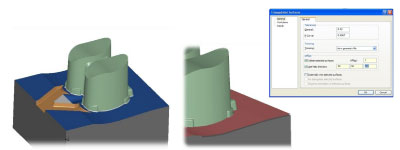

Although NCG CAM is not a modeling system, it has some functions that enable the user to modify and protect surfaces ready for  manufacture. manufacture.

Offset surface is a useful feature for the protection of the split-line or shut–off faces on a mould-tool. It is ideally suited to tool repair work where you want to stay off polished surfaces in the mould, further protecting those surfaces during machining operations. |